Our TECHNOLOGY PRODUCES SUSTAINABLE bioPLASTICs

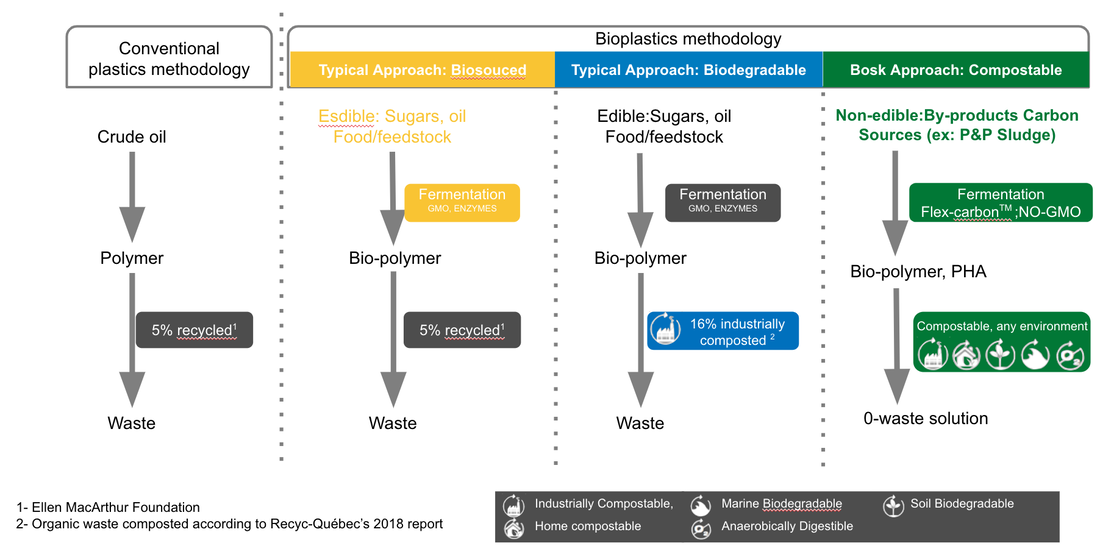

BOSK’s patent pending technology process constitutes a radical innovation in that it offers a fully compostable bioplastic at competitive cost.

Unlike most other PHAs on the market, our PHA does not contain or use any GMOs, is non-toxic and is made from forest industry renewable, untapped carbon sources.

We also provide a product performance that is comparable to petroleum based plastics in multiple applications.

BOSK bioplastics offers an innovative, cost effective and performance based solution to the global problem of plastic waste.

Unlike most other PHAs on the market, our PHA does not contain or use any GMOs, is non-toxic and is made from forest industry renewable, untapped carbon sources.

We also provide a product performance that is comparable to petroleum based plastics in multiple applications.

BOSK bioplastics offers an innovative, cost effective and performance based solution to the global problem of plastic waste.

the best of science

For more than 10 years, researchers at the INRS (Institut National de Recherche Scientifique) in Quebec have been developing a patent pending technology to produce a 100% natural molecule : PHA (polyhydroxyalkanoates), a biopolymer that can be substituted for conventional plastic and is truly compostable.

About Polyhydroxyalcanoates (PHA)

Polyhydroxyalkanoates or PHAs are a series of natural bio-benign materials similar to other natural materials like wood, other cellulose based materials, proteins and starch.

PHA materials can substitute petroleum plastics for many applications that often by design or improper waste management end up in the environment. Biodegradation of PHA materials in all environments (compost, soil, water) is comparable to or faster than cellulose (i.e. paper).

PHA materials can partly substitute any of the traditional fossil-based polymer families. Depending on type and grade, PHA materials can be used for injection molding, extrusion, thermoforming, 3D printing, etc. Also, their use in medical applications like sutures and wound closures is already commercial, since the material is bioresorbable.

PHA materials can substitute petroleum plastics for many applications that often by design or improper waste management end up in the environment. Biodegradation of PHA materials in all environments (compost, soil, water) is comparable to or faster than cellulose (i.e. paper).

PHA materials can partly substitute any of the traditional fossil-based polymer families. Depending on type and grade, PHA materials can be used for injection molding, extrusion, thermoforming, 3D printing, etc. Also, their use in medical applications like sutures and wound closures is already commercial, since the material is bioresorbable.

DESIGNED TO REDUCE OUR IMPACT ON THE ENVIRONMENT

BOSK makes no compromises. Every stage of our process is designed to generate a positive impact on the environment. We use untapped resources, non-toxic ingredients and we forbid the use GMOs or enzymes in our process.

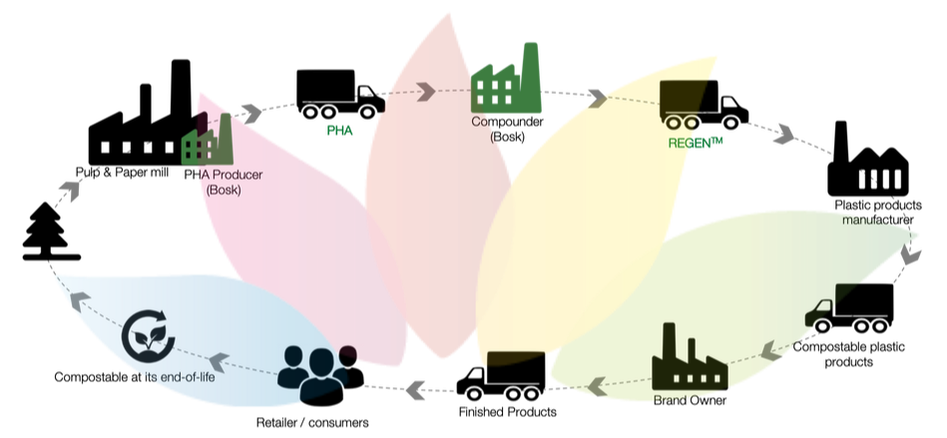

LIFE CYCLE OF BOSK’S COMPOSTABLE bioPLASTICs

BOSK's Bioproducts does not sell pure PHA. We use our PHA to manufacture REGEN™, our proprietary ready-to-use bioplastic resin that is certified biobased and fully compostable.

REGEN™ is processed into finished products/packaging by plastic manufacturers and then sold to consumers who can compost the products at the end of their useful life.

The life cycle of BOSK bioplastics offers a zero-waste alternative, based on the circular economy model (see below).

REGEN™ is processed into finished products/packaging by plastic manufacturers and then sold to consumers who can compost the products at the end of their useful life.

The life cycle of BOSK bioplastics offers a zero-waste alternative, based on the circular economy model (see below).

composting, a truly sustainable solution

Even recycled plastics have a limited useful life and will eventualy end-up in landfills, be incinerated, or enter the environement. Composting is the only solution to transform products back into basic natural elements that usefull and beneficial for the environment. Fully compostable bioplastics offers a viable and responsible end-of-life alternative for products and enables a truly zero waste solutions.

Be the first to know when products made with REGEN are available.

A canadian companyUne entreprise québécoise |

|